RECENT PROJECT ACTIVITY

Failure Investigations/Troubleshooting

- Failure investigation of (DC) emergency oil system which

resulted in significant damage to 14 MW steam turbine-generator

bearings and rotors.

[Click here to see photo]

- Failure investigation of 38 MW steam turbine low pressure

blading during commissioning.

[Click here to see photo]

- Investigation of thrust balance in a 53 MW steam turbine

which caused a hot running turbine thrust bearing.

- Failure investigation of 60 MW load gear for General

Electric Frame 6 gas turbine.

- Failure investigation of the high speed rotor from a main

feed pump turbine installed on a US Navy cruiser.

[Click here to see photo]

- Investigation of 18000 BHP steel mill blast furnace blower

and turbine driver [Click here to

see photo]

Failure Investigations and Repairs - Manufacturer Summary

Alstom

- 150 MW steam turbine HP blade failure due to corrosion, expert

witness for

the engineering firm

- GT24 B2, failure investigation of LPT3 turbine blade, expert

for

the insurance company

- 157 MW steam turbine HP stop valve diffuser failure, expert

for

the utility

- GT11, gas turbine silo combustor inner liner failure,

expert for the insurance company

General Electric

- D11 215 MW steam turbine main stop/control valve seat

failure, expert for the insurance company

- Frame 7EA gas turbine failure due to foreign object damage

of the compressor section, expert for the utility

- D3 175 MW steam turbine failure of the HP nozzle partitions

resulting in significant damage to the HP steam path, expert for

the insurance

company

- LM 6000 and 2500 failure investigation related to a total of

five

separate compressor and hot gas path incidents located in Asia

and USA, expert for

the insurance company

- H9/K3 325 MW steam turbine failure investigation of the

lube oil system resulting in significant bearing damage, expert

for the

insurance company

Siemens and Westinghouse

- 200 MW steam turbine life assessment for application in

cogeneration service in Thailand, expert for the utility

- 150

MW steam turbine failure investigation and repair of

cogeneration unit

where failure due to a transient operation resulting in severe

internal

rubs,expert for the utility

- 7.5 MW steam turbine evaluation to address performance

deterioration, expert for the utility

- 100 MW steam turbine in cogeneration service, evaluation to

address operation with high vibration, expert for the utility

- 150

MW frame RJX2606 (Westinghouse) failure investigtion of L-2

blades

resulting in significant damage to the steam path, expert for

the

insurance company

- 500 MW steam turbine thrust

bearing evaluation to assure reliable long-term evaluation after

turbine generator rerate, expert for the utility

- 100

MW Alstom/Siemens - Finspang (Sweden) steam turbine in

cogeneration

service, rotor repair after damage incident, expert for the

insurance

company

Dresser Rand

- 33

MW double extraction steam turbine generator failure

investigtion of

the HP nozzle plate bolting resulting in significant steam path

damage,

expert for the utility

- 50 MW double end drive steam

turbine generator failure investigation due to (a) stage 1 blade

locking feature, and (b) solid particle erosion,expert for the

utility

Expert Witness, Arbitration, and Mediation

- Failure of a 500 MW Westinghouse steam turbine during control

system commissioning, expert for the defendant

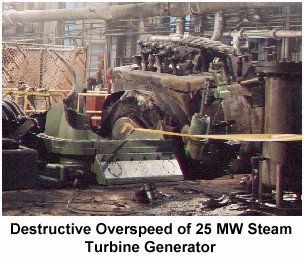

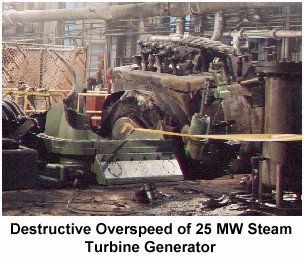

- Failure of a 10 MW steam turbine due to destructive overspeed

incident while testing the unit, expert for the defendant

- Represented

the plaintiff in an arbitration of a construction management

case

involving a complete cogeneration power plant in the Middle East

Due Diligence - Asian Steam Turbine Manufacturers

- Vendor evaluation of a 230 MW - 60Hz steam turbine

generator for a US utility, this is the first Chinese steam

turbine for

a US project, expert for the developer

- Vendor evaluation of a 150 MW - 60Hz steam turbine generator

for a project in Guatemala, expert for the developer

- Vendor

evaluation of 660 MW - 50Hz steam turbine generators (quantity =

6)

for project in India, subcritical steam conditions

- Vendor

evaluation of 660 MW - 50Hz steam turbine generators (quantity =

2)

for project in Saudi Arabia, subcritical steam conditions

- Vendor

qualification and evaluation specification for a 1000MW - 60Hz

steam

turbine generator for project in Asia with ultra super

critical

steam conditions and 45" last stage blades

- Evaluation

specification for a 1200 MW - 60Hz steam turbine for US power

station with the equipment supplied by a Japanese manufacturer,

expert

for third party engineering firm

- Vendor

evaluation of a 600 MW - 60Hz steam turbine generator for an

Asian

project, this is the first off 60 Hz design for the Chinese

manufacturer

Training

- Developed a steam turbine design course "Design and Major

Repairs of Large Steam Turbines for Utility Applications" and

presented

over 25 times worldwide to date

- Developed a

tutorial for large steam turbines which are applied with

ultra-supercritical steam conditions and presented several times

to

utility engineers and manufacturers

Predictive Maintenance Programs - route development for a

major boiler and machinery insurance company. Coordinated with

operating personnel to identify critical equipment for periodic

measurement of vibration and temperature to prevent failure and

improve and/or maintain plant reliability:

- Electric generating/refuse burning Steam Plant with Steam

Turbine in upstate NY

- Electric generating/chip burning Steam Plant with Steam

Turbine in upstate NY

- Electric generating/refuse burning Steam Plant with Steam

Turbine in South Carolina

- Combined Cycle COGEN with steam host in Northern California

- Electric generating/chip burning Steam Plant with Steam

Turbine in central MA

- 43 MW Central Station (Steam) in western PA

- Fully integrated chemical plant in Tennessee

Development Projects

- Large Electric Utility Project to investigate alternate

methods for repair of steam turbine diaphragms. Purpose of

project is

to reduce lead time of repair and cost

[Click here to see photo]

- Various utilities - in association with a major fluid film

bearing design and manufacturing company, work with utilities to

resolve long term steam turbine, generator, pump and fan

rotor/bearing

system vibration, maintenance or operability problems

- Chemical plant in central US, redesign centrifugal blower

rotor/bearing system and blower case to improve reliability and

correct

design defects

[Click here to see photo]

- Insurance Industry guidelines for contamination of large

utility steam systems

© 2012 Foster Cove Engineering fce@fostercove.com

Web design by Thinker

Software Systems